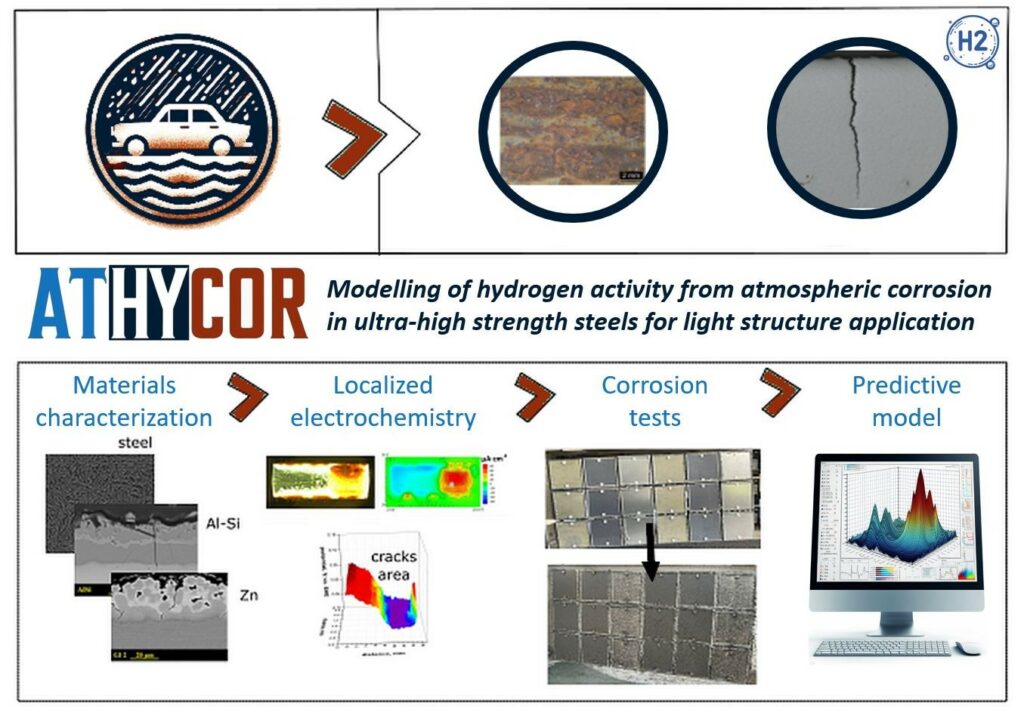

Modelling of hydrogen activity from atmospheric corrosion in ultra-high strength steels for light structure application

AtHyCor (RFCS – 101034041)

—

Start: 01/07/2021

Duration: 36 months

Coordinator: French Corrosion Institute

Participants: ArcelorMittal Maizières Research, Voestalpine, University of Prague, RISE Research Institutes of Sweden, Technical Institute of Lisbon (IST)

Budget: 1 906 026.05 €

EU contribution: 1 143 615.63 €

—

Steel in automotive industry excels as a material of choice thanks to the development of high-performance grades displaying excellent mechanical properties. However, the steel industry still faces major challenge that is to prove that their newest steel solutions will sustain the service conditions of a vehicle, particularly those related to hydrogen assisted cracking under atmospheric corrosion conditions. Indeed, ultra-high strength steels are known to be sensitive to hydrogen embrittlement and nowadays, from early steps, the fabrication processes are adapted to control the risks of delayed fracture for instance. Even the microstructures of advanced steels are tailored to decrease the sensitivity of the steels to hydrogen. However, atmospheric corrosion can be an additional source of hydrogen during service life, which was probably not so dangerous for low grades, but become critical for high strength steels with ultimate tensile strength above 1000 MPa. And this problem needs to be solved to make steel more competitive and to rise reliability.

The main scientific objective of this project is to develop a simulation tool that can model hydrogen entry and distribution into coated press-hardened steels (PHS) exposed to atmospheric corrosion conditions. The industrial aim of this project is thus to provide steel makers and car manufacturers with new data related to environmentally assisted fracture risks of ultra-high strength steels and with a simulation tool that could anticipate such risks. These main objectives can be divided into the following ones:

- New data for atmospheric corrosion and hydrogen entry in PHS

- To characterize and understand the corrosion mechanisms in simulated simplified atmospheric corrosion conditions (thin electrolyte film layer)

- To obtain quantitative data for the corrosion processes at localized scale using an advanced combination of electrochemical and analytical techniques

- To investigate the evolution in terms of composition, morphology and distribution of the water layer and corrosion products under atmospheric corrosion conditions

- To simulate various aggressive environments and the respective corrosion test conditions to reveal the main difference between accelerated corrosion tests and outdoor exposures and dependence on the corrosion mechanisms

- New method to evaluate local hydrogen content from atmospheric corrosion

- To quantify hydrogen entry into the steels due to atmospheric corrosion processes (galvanic coupling or free corrosion)

- To reveal important factors that govern hydrogen generation due to atmospheric corrosion

- To use experimental data in the simulation of simplified atmospheric corrosion processes of various coated high strength steels, considering cut edges and defects in the coating

- To model the hydrogen entry flux due to atmospheric corrosion processes as a function of environmental conditions and coating composition

- To tailor the model for application to more complex samples and structures

- To build multi-physics model that links surface (corrosion activity and hydrogen entry) and bulk (stress/strain distribution and hydrogen trapping) phenomena

- Prediction of hydrogen assisted cracking risks under atmospheric corrosion conditions

- To assess the risks of hydrogen assisted cracking for selected coated high strength steels under atmospheric corrosion conditions

- To use the model to anticipate the risks of hydrogen assisted fracture under various standard automotive test conditions

- To build a guideline for the prediction of hydrogen assisted failure of coated high strength steels under atmospheric corrosion conditions

- To make the simulation tool available to other European research teams in order to extent the applicability of the model

The AtHyCor project addresses several topics related to the limit of use of ultra-high strength steels in the automotive industry. The gathered knowledge and the new data sets and models will represent a clear progress beyond the state of the art in all aspects related to atmospheric corrosion, hydrogen entry and hydrogen assisted cracking risks of such steels. The way how the different aspects will be interlinked is an innovative concept of high relevance for the steel industry.

Publications (to be updated):

A. Nazarov, V. Helbert, F. Vucko, Scanning Kelvin Probe for Detection in Steel of Locations Enriched by Hydrogen and Prone to Cracking, Corrosion and Materials Degradation (2023) DOI: 10.3390/cmd4010010

F. Vucko, V. Helbert, A. Nazarov, Quantification of hydrogen flux from atmospheric corrosion of steel using scanning Kelvin probe technique, MDPI/Metals, 2023, DOI: 10.3390/met13081427

V. Helbert, A. Nazarov, M. Taryba, F. Vucko, F. Montemor, D. Thierry, Kinetics of corrosion reactions on press hardened steel in atmospheric conditions under thin electrolyte films, Electrochimica Acta (2023) DOI: 10.1016/j.electacta.2023.142500

Presentations at conferences:

V. Helbert (IC), Insight into atmospheric corrosion mechanism of Press Hardened Steel using local electrochemical techniques, Eurocorr 2023, Bruxelles, Belgium

F. Vucko (IC), Hydrogen embrittlement of high strength press-hardened steels under simulated atmospheric corrosion conditions, Eurocorr 2023, Bruxelles, Belgium

A. Nazarov (IC), Scanning Kelvin Probe for Local Detection of Stress and Hydrogen in High Strength Steels, 74th Annual ISE Meeting, 2023, Lyon, France

V. Helbert (IC), Polarisation curves for ultra-high strength steels under atmospheric corrosion conditions using Scanning Kelvin Probe, EMCR 2022, St Pierre d’Oléron, France

D. Rudomilova (UP), SKP study of corrosion-induced hydrogen entry into zinc-coated and bare advanced high strength steel, Eurocorr 2022, Berlin, Germany

N. Macháčková (UP), Effect of environmental parameters on the entry of atomic hydrogen into the structure of advanced high-strength steels due to atmospheric corrosion, Eurocorr 2022, Berlin, Germany

F. Vucko (IC), Hydrogen activity during corrosion of high strength steel under simulated atmospheric corrosion conditions, Eurocorr 2022, Berlin, Germany

T. Zavalis (RISE), Atmospheric corrosion models – Opportunities and challenges, 8th International Seminar in the field of Automotive Corrosion 2022, Stockholm, Sweden

F. Vucko (IC), Investigation of stress corrosion cracking assisted by hydrogen of advanced high strength steels under atmospheric corrosion conditions, 8th International Seminar in the field of Automotive Corrosion 2022, Stockholm, Sweden

This project has received funding from the Research Fund for Coal and Steel under grant agreement No 101034041