Mn austenitic stainless and non-stainless steels for hydrogen applications:

production, transport and storage

HISTORY (RFCS – 101155823)

—

Start: 2024

Duration: 42 months

Coordinator: French Corrosion Institute

Participants: Idonial, Sidenor, University of Prague, IFPEN, Ugitech

Budget: 2 557 598.17 €

EU contribution: 1 534 558.89 €

—

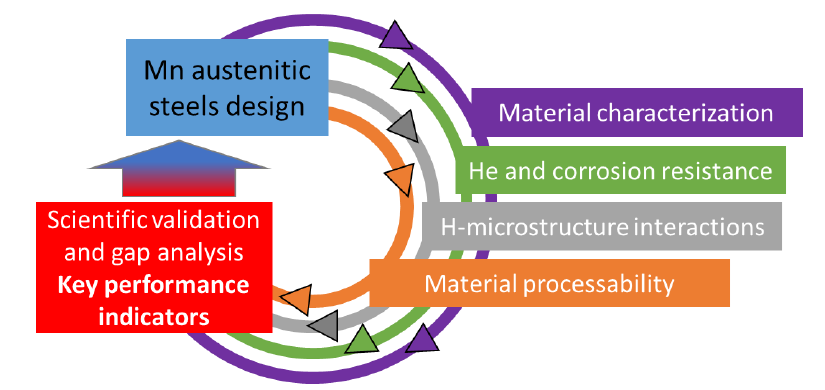

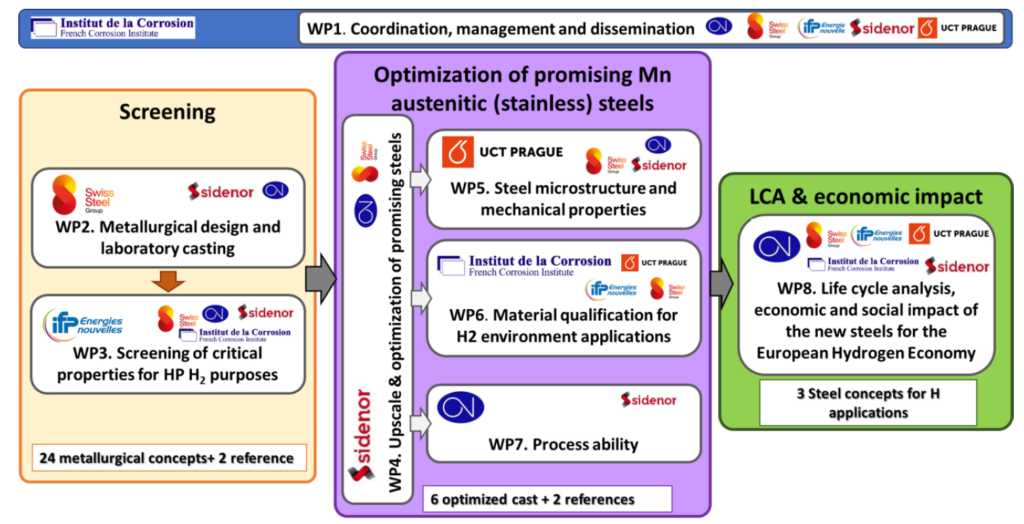

The goal of the HYSTORY project is to develop Mn austenitic stainless and non stainless steels via high throughput metallurgy screening. The project targets the development of innovative grades for hydrogen production (PEM electrolysers), cryo-compressed hydrogen storage and compressed hydrogen transport. Therefore, the susceptibility to hydrogen embrittlement and the interaction between hydrogen and the microstructures will be deeply studied. The positioning of the novel developed grades versus current steel solutions (austenitic stainless 316L and ferritic line pipe grade) will be assessed in terms of hydrogen embrittlement susceptibility and steel manufacturing competitiveness. In addition, key performance indicators defined for each studied property and weight algorithm will assist the optimization of the metallurgies and the alloys comparison.

For each specific market, dedicated targets have been defined to hasten the applicability of those new steel concepts:

1. Hydrogen production: proton exchange membrane (PEM) electrolyser. To achieve a capital cost of 500€/kW it is targeted to keep same formability and PEM applicability as the 316L steel and obtain a gain of 20% on the strength.

2. Hydrogen storage and transportation: liquid hydrogen transport. 316L steels show very important sensitivity to hydrogen embrittlement at temperatures between -50°C and -100°C. For cryogenic applications it is therefore targeted an air impact toughness at low temperature at minimum equal to the 316L and an increase by 30% of the hydrogen embrittlement resistance between -50 and -100°C.

3. Hydrogen storage and transport: compressed hydrogen. In order to use the new concepts on valves and fittings it is targeted to obtain at minimum the same good formability and processability as for the 316L and an improved Hydrogen Assisted Fatigue Crack Growth by a factor X10.

It is important to note that no unique metallurgical solution for the three markets is expected as outcome of the HYSTORY project. On the contrary, adapted metallurgical solutions for each application as function of the application demands is targeted, meaning Mn austenitic stainless and non-stainless metallurgical concepts.

HYSTORY is aligned with Europe’s Green Deal and its policies on sustainability and efficient use of resources. The project will address the EU Hydrogen Strategy as a fundamental way to “boost clean hydrogen production in Europe, as hydrogen can be used as a feedstock, a fuel or an energy carrier and storage, and has many possible applications which would reduce greenhouse gas emission across industry, transport, power and building sectors”.